Steel structures play a vital role in modern construction, offering strength, durability, and flexibility for buildings, industrial facilities, pipe racks, platforms, tanks, and bridges. At DesignCrafts, we specialize in designing reliable and cost-effective steel structures that meet international engineering standards. In this article, we will explore the most important parts of designing steel structures, covering everything from load considerations to detailing and safety.

1. Understanding Loads and Forces

Every steel structure must withstand different types of loads. Correct load analysis ensures safety and long-term stability.

- Dead Loads (DL): The permanent weight of the structure itself.

- Live Loads (LL): Variable loads such as people, vehicles, or stored materials.

- Wind Loads: Lateral forces acting on tall structures or open platforms.

- Seismic Loads: Forces caused by earthquakes, critical in seismic-prone regions.

- Environmental Loads: Snow, rain, and temperature effects.

👉 SEO Tip: Engineers must apply standards like ASCE, Eurocode, and AISC for accurate load calculations.

2. Material Selection

Choosing the right steel grade directly affects strength, weldability, and cost.

- Mild Steel (S235, S275, S355): Common in structural design.

- High-Strength Low-Alloy Steel: For heavy-duty structures.

- Stainless Steel: Used where corrosion resistance is essential.

👉 Selecting materials based on design pressure, environmental conditions, and service life is a key engineering decision.

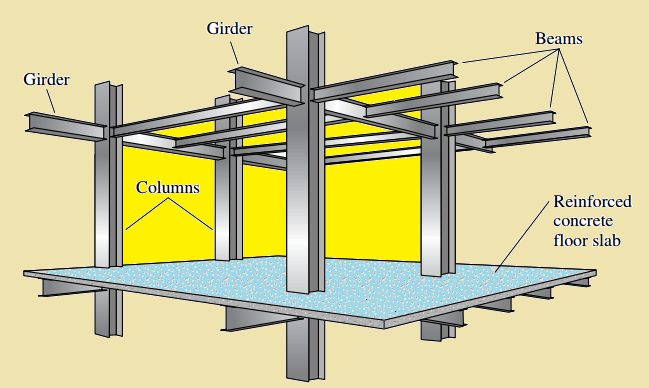

3. Structural Member Design

Steel structures consist of multiple members that must be designed with precision:

- Beams: Carry bending loads.

- Columns: Resist axial loads and buckling.

- Bracings: Provide lateral stability.

- Trusses: Used for large spans like roofs and bridges.

- Plates and Slabs: For floors, platforms, and tanks.

👉 Using finite element analysis (FEA) tools helps optimize thickness, size, and geometry.

4. Connections and Joints

Connections are the backbone of a steel structure. Poorly designed joints can lead to failure even if the members are strong.

- Bolted Connections: Easy to assemble and maintain.

- Welded Connections: Provide high strength but require skilled labor.

- Hybrid Systems: Combining bolts and welds for efficiency.

👉 Following standards like AISC, AWS, and EN 1993 ensures safety and reliability.

5. Safety and Stability

Safety is the heart of structural engineering. Engineers must check for:

- Buckling of columns.

- Lateral-torsional buckling of beams.

- Overall structural stability.

- Fire resistance and protection.

👉 Applying safety factors ensures that steel structures withstand unexpected stresses.

6. Corrosion Protection

Steel is vulnerable to corrosion, especially in oil & gas, refinery, and marine projects. Protection methods include:

- Hot-Dip Galvanization.

- Epoxy and Polyurethane Coatings.

- Cathodic Protection.

👉 At DesignCrafts, we often use Jotun industrial coatings for maximum protection of tanks and platforms.

7. Detailing and Fabrication

Structural detailing translates design into shop drawings for fabrication.

- Clear 2D and 3D drawings (AutoCAD, Tekla, SolidWorks).

- Proper welding symbols and bolt sizes.

- Efficient fabrication sequences.

👉 Accurate detailing reduces material waste and ensures faster erection.

8. Erection and Installation

The final step is erecting the steel structure on-site:

- Proper lifting plans and cranes.

- Alignment and leveling.

- Quality inspection and testing.

👉 Following HSE (Health, Safety & Environment) guidelines during erection ensures worker safety.

🔑 Conclusion

The most important parts of designing steel structures include load analysis, material selection, member design, connections, safety, corrosion protection, detailing, and erection. Each stage requires technical expertise, advanced software, and strict adherence to international standards.

At DesignCrafts, we combine engineering knowledge with practical field experience to deliver safe, durable, and cost-effective steel structures for refineries, storage tanks, pipe racks, and industrial facilities.